Suppose you’ve ever wondered why we suddenly get angry during a five-minute power failure. In that case, the contemporary world is so heavily reliant on electrical energy to function correctly. In reality, it’s difficult to understand how our forefathers and foremothers survived without all of the benefits of electricity. Everything in life becomes significantly simpler as a result, which is why governments invest millions of dollars in supplying families and enterprises with dependable energy.

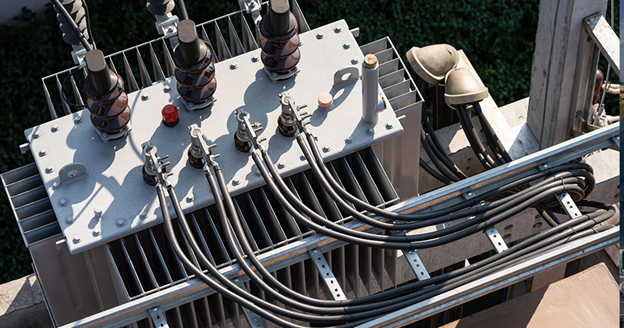

Because power transformers are critical players in electrical distribution, it is understandable why we want them to remain operational around the clock. Whatever the application, whether it’s a switchyard or even a substation, we rely on these parts to perform at a high level, which may become an issue when there is an oil leak.

And, more specifically, what does oil have to do with power transformers? Simply defined, this so-called dielectric oil is indeed an electrical insulator used to minimize the amount of heat created by the high-voltage transformer during its operation. This chemical is very hazardous to the safety of your employees and the environment. Therefore you must take prompt and cost-effective measures to stop it from leaking into the environment.

If there is an oil leak, nothing within the transformer can be used to disperse the heat generated. As a result, the power supply may be of poor quality. As you might guess, it also has an adverse effect on solid insulation, causing it to deteriorate much more quickly. You should also know that gases such as nitrogen and oxygen may seep into the transformer’s oil and cause harm, as well as moisture that could decrease the transformer’s lifespan.

A potential fire hazard

Suppose you ignore the problems with your oil-filled transformers for an extended period. In that case, they might represent serious environmental problems. It’s because they contain a significant amount of oil, which, when combined with the high voltage components within, creates a lethal combination. After the oil ceases to be dielectric, it vaporizes, resulting in a gas that cannot expand due to inertia, putting the surrounding area under pressure. Eventually, the static pressure inside the tank rises, which might cause an explosion or a fire within the tank.

Luckily, depressurization may be used to safeguard the transformer from being damaged. This approach immediately eliminates the oil and gas combination, allowing the situation to quickly bounce back. Even though these horrific stories are comparatively rare, they serve as a warning of exactly how dangerous a malfunctioning transformer can be.

Identifying the issue

It is not necessary to be an experienced electrical engineer to detect a transformer leak. All that is required is to thoroughly examine the parts and seek indicators typical to most power transformers. You’ll be able to assist the repairmen in diagnosing the problem much more quickly.

The typical loud screaming sound that comes from the interior, for example, is one such example. Once you understand what is causing it, it may be rather frightening, but it can also be quite beneficial. Then there’s the matter of strange warmth to contend with.

Suppose the temperature is too high in a normal setting and lasts for an extended period of time. In that case, it could be an indication of an oil leak. You can see oil shooting out of the safety valve or seeping through the oil tank in terms of visual appearance. A shift in the color of the oil is yet another warning indication.

There are a number of things you can do to ensure that your transformer is properly maintained. First of all, you should measure the temperature to ensure that it is within normal range. You’ll be able to tell if it’s warmer or cooler by checking the oil level gauge.

We’ve talked about noise in the past. Even though this symptom is more common in dry-type transformers, it can also be seen in their oil-filled equivalents. Another approach that may be used is to compare the current and lead voltage to the power ratings. Check this website for more.

Taking care of the issue

Maybe you’re wondering if repairing these sorts of leaks is something that can be accomplished by the average homeowner. The answer to that is yes and no at the same time. Perhaps, because there are certain things you can do yourself in situations of minor draining, but no, because more complex techniques of sealing necessitate the attention of a skilled professional team with years of expertise.

One technique that might be used is to use glue to repair a drain. A high-quality adhesive is, in reality, a highly effective solution, even though it may appear to be an amateur answer at first glance. You can work on transformer repairs without having to turn the entire system off, which is a huge advantage. Following that, the adhesive has excellent durability and flexibility, and it can withstand adverse weather conditions. The majority of the time, these simple fixes take just a few minutes.

Dry-type and oil-filled transformers are the two most common types of transformers. The former is more substantial and less efficient; it has a low voltage range and significant electrical inefficiencies. Oil transforms are not as huge in scale, but they are more productive.

Additionally, they leave a reduced carbon imprint, making the world a safer place to live in overall. As a result, dry-type is less difficult to maintain and is far more resilient to pollutants. At the same time, oil requires periodic testing to determine whether or not it is contaminated.

Making the right choice

Oil leak sealing should only be considered as a temporary solution. Your transformer won’t become a completely new component overnight. Still, it will perform admirably until the time comes for a more permanent solution, maybe even replacement. In most cases, a transformer leak repair can turn out the best solution possible!

A trustworthy supplier will give you a clear and accurate cost plan for such repair work before the service is performed. Gasket replacement and oil filter replacement can cost a lot of money, so ensure you pick the proper professionals for the job.